WELDED & SEMI WELDED

WELDED HEAR EXCHANGER

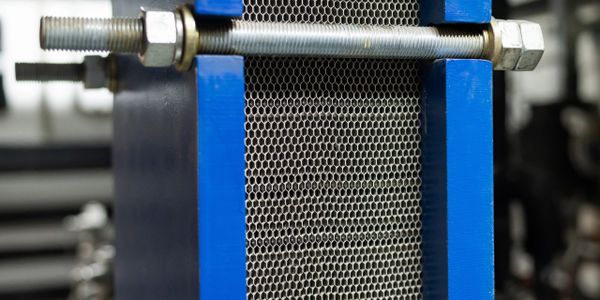

A welded heat exchanger is built by permanently joining metal plates or components through welding, eliminating the need for gaskets. This fully sealed construction allows it to handle extremely high pressures, temperatures, and aggressive or corrosive fluids. Because it’s completely welded, it’s highly durable and leak-proof—but it cannot be easily opened for cleaning, which makes it best suited for clean or closed-loop systems in industries like chemical processing or power generation

SEMI WELDED HEAT EXCHANGER

A semi-welded heat exchanger combines features of both gasketed and welded designs. In this type, pairs of plates are welded together to form sealed channels for one fluid, while the other fluid flows between these pairs in gasketed channels. This hybrid setup allows one side to handle aggressive media while the other side remains serviceable. Semi-welded exchangers offer a balance between resistance to harsh conditions and ease of maintenance, making them ideal for applications like ammonia refrigeration or chemical processes.

APPLICATIONS,ADVANTAGE,CONNECTIONS & PORTSIZING

Get Inspired by Our Heating Equipment Showcase

Universal Core Flow Solutions Inc.

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.